A team of researchers headed by Hyeonggeun Yu, a former postdoc within the Department of Materials Science and Engineering at the North Carolina State University, (Raleigh, North Carolina) are developing a new approach for visualizing images that derive from ultrasound. The new approach is much simpler than conventional methods and has the potential to significantly reduce the cost to implement ultrasound imaging in devices.

A recent article on this topic is entitled “Direct Acoustic Imaging using a Piezoelectric Organic Light-Emitting Diode.” It was published in ACS Appl. Mater. Interfaces 2020, 12, 32, 36409 – 36416. A copy of the article is available for purchase here.

First a few words of background information.

Conventional ultrasound imaging devices require acoustic scanning of a target object using a piezoelectric transducer array to detect ultrasonic waves. These waves are then converted into an electrical signal. The signal is then sent to a computer where it is processed so as to enable conversion into a visible image. Conventional ultrasound imaging devices of this type can be quite expensive because they include an array of thousands of transducer elements and this, in turn, drives up manufacturing costs.

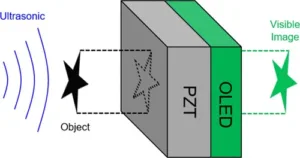

The team has created a novel device to address these issues by effectively eliminating the need for electrical signal processing. The details can be explained by paraphrasing the technical article. In the device, an OLED is fabricated on top of a layer of lead zirconate titanate (PZT), a piezoelectric crystal. By this means, an acousto-optical piezoelectric OLED (p-OLED) transducer is created that can convert an acoustic wave profile directly to an optical image. Due to the integrated nature of the device architecture, the resulting p-OLED demonstrates a high acousto-optic conversion efficiency at the resonance frequency, providing a piezoelectric field to drive the OLED. By incorporating an electrode array in the p-OLED, an ultrasound imaging device is created that operates without the need for conventional signal processing.

A simplified schematic of the newly developed ultrasound imaging device.

Using this new approach, the researchers believe that “We can make ultrasound receiver-display units for $100 or so.” In their article, the researchers explain that the prototype device was intended to demonstrate proof-of-concept and incorporates an OLED array having a not very useful resolution of 10 pixels by 10 pixels. Looking towards future development work, the researchers explain that they can easily increase the resolution to a more useful 500 pixels by 500 pixels.

The article concludes with a statement by the researchers that are interested in collaborating with industry partners to explore commercial applications.

As a bit of an afterthought, I would like to propose a sort of technological family history that may or may not have any historical accuracy. Although the structure and functioning of the ultrasound imaging device is quite different, it seemed (at least to me) to be a “descendant” of the liquid crystal light valve developed by Hughes back in the mid-1980s. In the Hughes device, a light image was focused on a photoelectric layer that transferred an electrical pattern to a liquid crystal layer that visualized the image. In fact, it occurs to me that the basic idea could be taken even further back in time….to the earliest days of liquid crystal technology….to a device developed by Jim Fergason at Westinghouse around 1960. It was called a Mesoscope. In this device, a temperature pattern generated by an IR image focused on a black surface was transferred to a layer of cholesteric liquid crystal that served to visualize the image. What do you think? Any validity to this genealogy? -Arthur Berman

North Carolina State University, Xiaoning Jiang, 919-515-5240, [email protected]