A team of researchers led by Professor Kyung-Chul Choi within the Faculty of Electrical and Electronic Engineering at the Korea Advanced Institute of Science and Technology (KAIST) (Daejeon, Korea) is developing “stretchable OLEDs that are compliant and maintain their performance under high-strain deformation.”

First, a few words of background information.

Part of the definition of a stretchable OLED is that it can be elongated and then restored to its original shape while maintaining high efficiency and stability. Unfortunately, one reality of the current generation of stretchable OLEDs is that the stretching process inevitably causes the formation of thin wrinkles in the substrate. The size, shape and pattern of the induced wrinkles is variable and causes irregular distortions in the substrate. This, in turn, causes OLED pixels laminated to such elastic substrates to vary in their light output. In addition, it has been observed that, after stretching, the electrical conductivity of electrodes on stretchable OLEDs exhibit lower efficiency.

To address these issues, the team investigated stretchable OLEDs that were fabricated including a thermal evaporation process to produce desired patterns on stress-relieved substrates. It was hoped that OLEDs fabricated using this approach would not only mitigate the deficiencies found in prior art stretchable OLEDs but do so without the need to find new materials or the use of a pre-strained fabrication process.

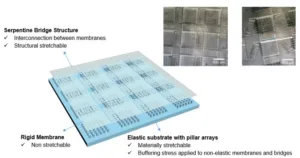

More specifically, the team created a substrate that is biaxially stretchable using an approach based on bonding together two substrate layers. A pattern of flexible, serpentine bridges was integrated into the upper substrate. The bridges serve to make stretchable the otherwise ridged upper substrate. Surface relief, island structures were integrated onto the lower, elastic substrate. These were composed of highly flexible, bonded arrays of elastic pillars. The pillars bond the top substrate to the bottom substrate and serve to decentralize the stress at the locations of bridges when strain is applied.

An illustration of the newly developed stretchable substrate appear to the left in the figure below. In the upper right of the figure are two photographs of an actual substrate. The photo to the left is the substrate in an unstretched state. The photograph to the right illustrates the distortion when the substrate is stretched in along one axis.

Illustration of the newly developed stretchable substrate. The upper right of the figure includes photos of an actual substrate in the unstretched state (left) and stretched along one axis (right).

An interesting video appended to the end of this article illustrates a substrate being stretched along one axis.

A recent article reporting results of work on stretchable OLEDs by the researchers is entitled “Two-dimensionally stretchable organic light-emitting diode with elastic pillar arrays for stress-relief.” It was published in Nano Lett. 2020, 20, 3, 1526-1535. A copy of the article is available for purchase here.

In this article, the researchers confirmed the advantages of the structures utilized in their approach using mechanical simulation tools. They confirmed that the structures effectively lessen the applied stress of interconnections as well as stress in the active areas when the substrate is in a stretched state.

The article also discuss details and presents data related to what the researcher’s describe as a successful effort to fabricate stretchable red, green and blue OLEDs. In addition, they report little difficulty with material selection as “practical processes were conducted with stress-relief substrates.”

The researchers conclude their article with the statement that the

“stretchable OLEDs were mechanically stable and have two-dimensional stretchability, which is superior to only one-direction stretchable electronics, opening the way for practical applications like wearable electronics and health monitoring systems.”

– Arthur Berman

KAIST Advanced Display and Nano Convergence Lab, Kyung-Chul Choi, +82-42-350-5482, [email protected]