Solar-Tectic LLC (Briarcliff Manor, NY) is promoting a technology called Low Temperature single Crystal Silicon (LT1CS). The primary focus of the technology is in solar cells but use also extends to display applications. This article focuses on two of the display-related applications.

First a few words of background information.

A continuing challenge in display technology is achieving a Thin Film Transistor (TFT) pixel switching backplane that is cost effective to manufacture and that can drive display pixels with stability over an extended period of time.

Several companies in the display industry have addressed this challenge in the manufacture of backplanes for small and medium sized AMOLEDs, LCDs and MicroLED displays by the use of Low Temperature Polysilicon (LTPS) technology. None-the-less, the LTPS process is “difficult to scale to large sizes, in addition to having issues of material waste and acceptable but less than ideal uniformity.”

LTPS produces polycrystalline silicon. It has been demonstrated that the performance of oriented or aligned crystalline thin films is superior to polycrystalline thin films.

Aligned Thin Films Need Quartz

At this time, the production of aligned crystalline thin film TFTs requires fabrication on a quartz substrate. The reason for this is that quartz is needed to survive the high temperature necessary for quality film growth.

Solar-Tectic’s LT1CS technology can produce a single crystal silicon TFT backplane using a low temperature process. This, in turn, allows the use of ordinary soda lime glass as the substrate. It follows that the Solar-Tectic approach can, in principle, reduce the cost of producing a backplane .

A distinguishing feature of the Solar-Tectic approach is that the silicon crystals have a preferred orientation, being highly c-axis aligned or “textured.” More specifically, the Solar-Tectic approach accomplishes the deposition of a continuous, highly crystalline thin film of silicon on ordinary soda lime glass via an extremely highly textured MgO buffer layer. A conventional electron beam evaporation method is used for the deposition. In addition, the new LT1CS process can achieve films with large grains or crystals which also enhance performance in a display backplane.

Electron mobility in textured, aligned thin silicon films would be higher than electron mobility in IGZO (indium gallium zinc oxide) which is another contender to replace LTPS. In addition, the uniformity of films produced by LT1CS technology would also be better than that produced by IGZO. Furthermore, IGZO uses the expensive rare earth elements indium and gallium. This could increase IGZO cost compared to LT1CS which uses inexpensive silicon.

It can be noted that Solar-Tectic’s LT1CS technology is similar to c-axis aligned IGZO but uses silicon rather than indium and gallium. The company comments that “In a way, one could say that LT1CS does for silicon what c-axis aligned IGZO does for IGZO.”

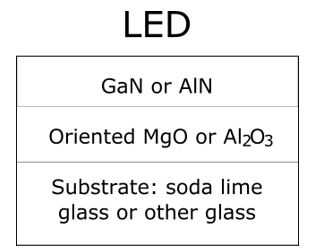

The initial application targeted for the new TFT backplane technology is the making of OLED displays. Beyond that, the company says that its new technology also applies to III-V materials like GaN which can be used in MicroLEDs in which the III-V materials are combined with silicon TFTs. An illustration of the generic layer structure in a substrate prepared using the Solar-Tectic process appears in the figure below.

An illustration of the generic layer structure utilized by the Solar-Tectic process.

An illustration of the generic layer structure utilized by the Solar-Tectic process.

New Sapphire Glass

Another potential application of Solar-Tectic technology in electronic devices is as a new kind sapphire glass.

“The new sapphire glass production technique involves the deposition of a highly transparent crystalline Al2O3 thin-film on ordinary soda lime glass, via a thin buffer layer, using conventional e-beam evaporation. By this means, a material is achieved which is much less expensive and much lighter than single crystal sapphire. It is also easily scalable for manufacturing and commercialization. The sapphire film is extremely thin which is important for cost reduction in manufacturing.”

The new sapphire glass has demonstrated a hardness of MOHS 8. (“The MOHS scale of mineral hardness is a qualitative ordinal scale characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material.”) Single crystal sapphire has a MOHS 9. Therefore, the Solar-Tectic sapphire glass is close to single crystal sapphire in hardness. The company claims that this is the first time this hardness has ever been achieved on ordinary soda lime glass.

Due to the material’s hardness, one display related application of sapphire glass is as a display cover.

Solar-Tectic is also developing a thin film production approach using a laser rather than an e-beam. In future development work, Solar-Tectic plans to optimize the films with the aim of achieving MOHS 9. Another goal is to develop the capability to deposit the films on all kinds of glass substrates.

In sum, Solar-Tectic hopes that their technology will replace now dominant LTPS technology in future high end mobile displays. The Solar-Tectic web site lists several patents that have been issued related to their technology. The company web site also indicates that the technology is available for licensing. -Arthur Berman