Additive Manufacturing (AM), better known as 3D printing, has taken off since a patent on the topic was issued in 1984 to Charles Hull who used a photo-crosslinkable polymer material. Most current 3D printing technology dates to this patent.

Researchers at MIT have recently published a paper on the use of optical grade glass for 3D printing. Previous efforts to make optical quality parts using 3D printing have used optical plastics. While these experiments using plastic have actually made usable parts, the quality has not matched the quality of optical plastic parts made with conventional tooling and that tooling tends to be very expensive. For some display applications, for example the lenticular arrays in autostereoscopic displays, optical plastics are the material of choice. For other display applications plastic parts simply won’t do. For example, the power levels encountered in the illumination path of a projector largely prohibit the use of plastic: glass is required. Some of these parts such as lenticular integrators have complex shapes and also require expensive tooling.

LED projector illumination paths can include shapes that are even more complex than the shapes used in lamp-based projectors. Current LED power densities allow the use of plastic parts. However, if made of glass, these designs might also be used in the higher power densities of lamp, laser and laser-phosphor systems, increasing their efficiency. Head mounted displays (HMD) and other near-to-eye (NTE) displays are another category of display optics that sometimes require complex optical shapes.

Glass, however, is very difficult to work with in a 3D printing application due to its high melting temperature and high viscosity. While two techniques have been developed to 3D print glass, sintering of small glass particles printed with a binder and selective laser melting, neither technique produces parts of satisfactory optical quality for use in displays. In addition, the parts lack the strength of glass parts made with conventional optical fabrication techniques.

Three researchers at the Massachusetts Institute of Technology (MIT), John Klein of the Media Lab, Michael Stern of the Department of Mechanical Engineering and Giorgia Franchin of the Department of Material Science and Engineering Glass Lab, led the team of ten from MIT, University of Padova, Harvard and Penn State in the 3D printing project. The technique uses controlled extrusion of glass, a well known technology they say dates back to ancient Mesopotamia. Extrusion of molten glass has two problems.

First, the glass is very hot with a softening point typically >1000°C but as high as 1600°C for some glass formulations and anything that comes in contact with the molten glass must be able to tolerate this temperature for extended periods of time. In particular, the 3D printing orifice must tolerate this temperature and show minimal erosion as the glass flows through it. The second problem with glass is that its viscosity varies very rapidly with temperature, so temperature must be carefully controlled to deposit the glass at a predictable rate. And, of course, a predictable deposition rate is required for the accurate manufacturing of parts using 3D printing.

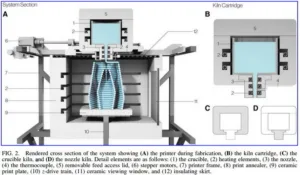

A further complication of 3D printing with molten glass is the glass, after printing, must be cooled slowly and a controllable rate to avoid cracking or other problems. This means the printing volume must be in an oven. The complete MIT 3D printing apparatus is shown in the figure above.

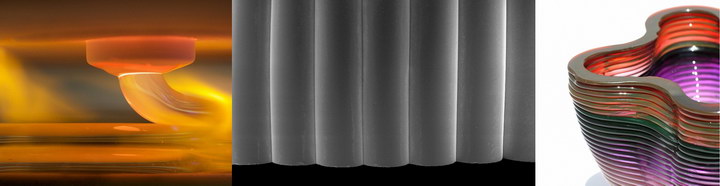

3D Printing with glass: Left, the glass being extruded from a ceramic orifice; Center, a scanning electron microscope image of the surface of a printed glass prism; Right, 3D art glass showing how the color of the glass can be varied.

There are a number of limitations in the techniques developed (so far) at MIT. First, the glass from the crucible (1) is delivered by gravity through the nozzle (3). This not only limits flow rates but also does not allow the use of small nozzles, which are likely to be required for parts for display systems. Second, there is no valve to control the flow of the glass. A very crude “valve” is made by lowering the temperature of the nozzle to the point where glass no longer flows through it. Clearly this valve action does not have the speed required for most 3D printing applications. Finally, the shapes produced are not exactly as predicted by the 3D CAD software used to design the parts.

The MIT researchers have ideas to solve all these problems, and others they have identified as well. For the glass flow, they expect to be able to use either a piston or compressed air to move the glass, rather than just gravity. This will allow the use of smaller nozzles to produce more detailed parts. Flow control can be done with high-speed, high temperature glass “scissors” under control of the software. Current scissors in the system are under the control of a graduate student. Finally, they have some ideas as to why the shapes are not exact. It seems to relate to the issue of the adhesion of hot extruded glass to cooler glass extruded earlier. Once a problem like this is identified, it can be compensated for in the controlling software.

With all its limitations, this work at MIT shows potential for significant future use in optical systems. The authors said, “Currently, we are observing how geometrical complexity can be leveraged for engineering gain, particularly in the aerospace industry in some cases improving performance by 40% or more. As designers learn to utilize this new freedom in glass manufacturing, it is expected that a whole range of novel applications will be discovered.”

Geometrical complexity is an inherent part of may display systems, including LCD backlights, autostereoscopic displays and projector collection optics. Even if 3D printing with glass does not prove economically viable for volume manufacturing, it may allow prototype construction at greatly reduced costs compared to conventional tooling and production techniques.

The developers of this technology have published an article in the on-line journal 3D Printing And Additive Manufacturing, Volume 2, Number 3, 2015 DOI: 10.1089/3dp.2015.0021. This article can be downloaded at no cost from http://tinyurl.com/psxewjr. Additional information, including a 4 minute video, is posted on the MIT website at http://tinyurl.com/nwtksol –Matthew Brennesholtz